In-Mold Decorations: Integrating Style and Production Excellence

Grasping In-Mold Decorations: Techniques, Fads, and Finest Practices for Optimum Results

In the world of production, the art of in-mold decors stands as a pivotal element of item style and production. In-Mold Decorations. By delving right into the techniques, fads, and ideal methods that underpin successful in-mold decor procedures, companies can unlock a realm of opportunities that not just elevate the visual allure of their items but also simplify production performance and reinforce consumer interaction.

Product Choice

Material selection is a crucial facet of grasping in-mold decors, as it directly influences the top quality and durability of the end product. When choosing products for in-mold decorations, it is vital to take into consideration factors such as compatibility with the molding procedure, the preferred visual outcome, and the environmental problems the item will deal with. Polycarbonate materials like polypropylene, polycarbonate, and abdominal are typically made use of for in-mold decorations due to their versatility and capability to achieve complex designs. These materials provide superb moldability, making it possible for manufacturers to produce intricate shapes and patterns with accuracy.

Furthermore, products with high heat resistance are liked for in-mold decors, specifically for items that will certainly be subjected to elevated temperature levels throughout their lifecycle. By thoroughly choosing the ideal material for in-mold designs, manufacturers can improve the total high quality and resilience of their products, fulfilling the expectations of both end-users and customers - In-Mold Decorations.

Layout Advancement

An important element in progressing the field of in-mold designs is the continual exploration and implementation of design advancement techniques. Layout development plays a vital function in boosting the aesthetic allure, capability, and general high quality of items produced using in-mold design processes. By including ingenious layout components, suppliers can distinguish their items in the marketplace, bring in customers, and stay in advance of rivals.

Among the key aspects of design innovation in in-mold decors is the assimilation of detailed patterns, textures, and graphics that were previously challenging to attain with typical design approaches. Advanced innovations such as 3D printing and digital design devices make it possible for developers to produce facility and detailed styles that can be effortlessly moved onto molded components. Additionally, the use of dynamic colors, metal surfaces, and unique impacts like gloss or matte appearances can additionally elevate the visual appeal of in-mold embellished items.

Moreover, design advancement prolongs beyond aesthetic appeals to incorporate functional enhancements such as ergonomic shapes, incorporated attributes, and personalized elements that accommodate particular user requirements. By accepting style technology, suppliers can unlock brand-new opportunities for personalization, product, and creativity distinction in the competitive landscape of in-mold decors.

Manufacturing Efficiency

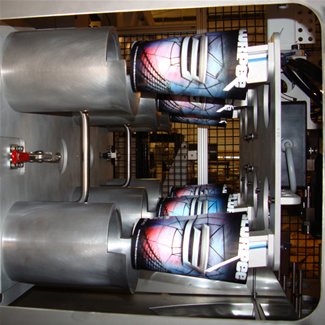

Efficient manufacturing processes are necessary for translating the cutting-edge designs created in the area of in-mold decors into high-quality completed items that fulfill market needs and customer assumptions. In the world of in-mold decors, manufacturing efficiency includes different vital facets that add to the general success of the manufacturing process. One vital element is the optimization of mold and mildew design and tooling to ensure smooth and exact decor transfer onto the end product. By fine-tuning mold and mildew arrangements and purchasing top quality tooling products, manufacturers can improve efficiency and uniformity in manufacturing.

Automation not only accelerates the production procedure however additionally improves accuracy and repeatability, leading to a much more top quality and uniform end product. Generally, an all natural method to manufacturing performance is paramount in optimizing the capacity of in-mold decor techniques and have a peek at this website accomplishing optimum results in the competitive market landscape.

Top Quality Control Actions

What are the key methods for making sure rigorous quality control steps in the world of in-mold decors? Quality control procedures are paramount in in-mold decoration processes to ensure the production of remarkable and high-grade finished items. One important strategy is the implementation of strenuous examination protocols at every stage of the production procedure. This involves conducting complete aesthetic evaluations, dimensional checks, and shade uniformity analyses to recognize any type of incongruities or issues early on.

Utilizing advanced innovations such as automated examination systems can also enhance the quality assurance process by providing dependable and precise data for evaluation. These systems can identify blemishes that may be missed out on by manual inspections, consequently improving overall item high quality and uniformity.

Regular training and growth programs for employees associated with the in-mold decor procedure can also add to preserving premium criteria. By informing staff on finest techniques, quality assumptions, and the relevance of interest to detail, business can promote a culture of top quality awareness throughout the organization.

Consumer Appeal

To enhance the marketability of in-mold decor products, understanding and catering to customer choices play an essential function in establishing their appeal and success. Customer charm in in-mold decorations is influenced by numerous aspects, consisting of style visual appeals, color options, longevity, and overall functionality. Consumers are progressively looking for individualized and one-of-a-kind products that reflect their individuality and design. Consequently, using personalization alternatives such as individualized styles, color variants, Look At This and textural elements can significantly boost the charm of in-mold design products.

Verdict

In-mold decorations use a reliable and functional way to improve product appearances. By meticulously picking materials, welcoming ingenious designs, maximizing manufacturing processes, carrying out quality assurance procedures, and focusing on customer appeal, manufacturers can achieve ideal outcomes. It is critical for companies to continuously adjust click for more and improve their techniques to stay competitive on the market. In-Mold Decorations. Understanding in-mold decorations needs an all natural approach that takes into consideration all elements of the production procedure to guarantee success.

In the world of manufacturing, the art of in-mold decors stands as an essential element of item design and production. Design technology plays a crucial role in enhancing the aesthetic charm, functionality, and overall high quality of products produced utilizing in-mold decoration processes.One of the key aspects of style innovation in in-mold decors is the assimilation of complex patterns, appearances, and graphics that were previously testing to accomplish with traditional design approaches.Effective manufacturing procedures are necessary for translating the ingenious designs established in the field of in-mold decorations into premium finished items that fulfill market demands and customer assumptions. Using customization alternatives such as customized designs, color variants, and textural elements can dramatically improve the appeal of in-mold decor items.